This startup is building smart AMRs to solve warehouse automation challenges

Bengaluru-based Anscer Robotics, with its Autonomous Mobile Robots, is gearing up to transform the warehousing space globally with its recent expansion.

In the age of automation, where speed and precision define competitive advantage, warehouse automation is no longer limited to large-scale corporations. Smaller robotics companies are also entering the space with adaptable technologies.

Bengaluru-based is one such player, building autonomous mobile robots designed to handle diverse material movement tasks. The startup develops autonomous mobile robots (AMRs) designed to simplify complex warehouse operations—from lifting to pallet movement with minimal human intervention.

According to Mordor Intelligence, India’s Warehouse Automation Market is estimated at $0.43 billion in 2025, and is expected to reach $1.42 billion by 2030, at a CAGR of 26.96%.

Since its founding in 2020, Anscer has focused on scalable automation that integrates smoothly into existing systems. With its recent seed funding of $2 million from Info Edge Ventures in February and a planned expansion into the US, it is planning to bring its AMRs to factory floors around the world.

Brains behind the bots

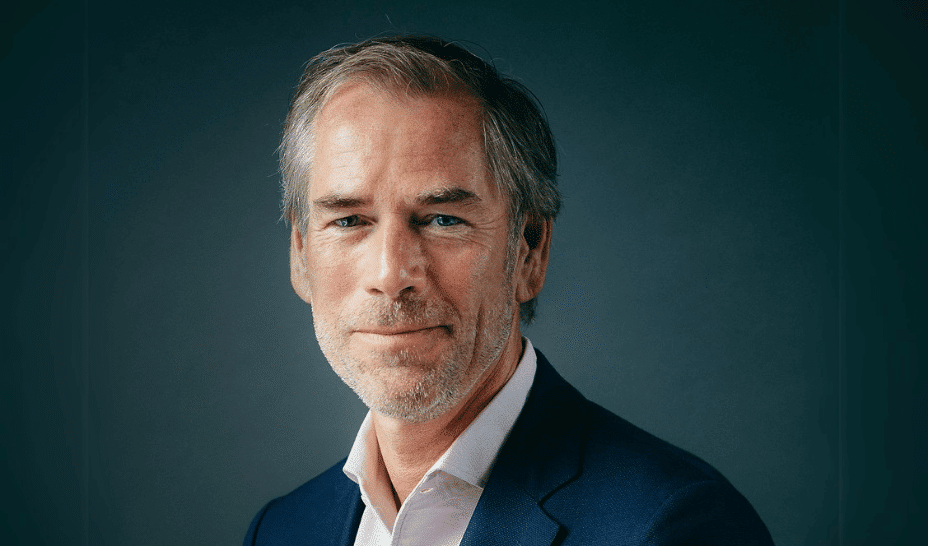

Anscer started off as a project with three engineers and a shared vision, Raghu Venkatesh, Co-founder, CBO, Anscer Robotics, tells YourStory.

Prior to Anscer, he had already had experience helming two other startups. After his second venture, a virtual reality company called Ploud.io shut down in 2015, Venkatesh used the space and the capital raised for the startup and collaborated with Bangalore MakeSpace and Open Source Creative Club to launch a makerspace for other creators and entrepreneurs. He met his (now) co-founders Ribin Mathew and Ebin Sunny between 2015-16.

Fresh out of college with engineering degrees, Mathew and Sunny had taken up driving cabs and trucks just to keep themselves afloat in the city, “Bengaluru is every tech guy's dream,” exclaims Venkatesh, who saw potential in two engineers with a knack for hardware.

“They showed me a bionic arm, and they didn't have money to make it electrical, so they used all mechanical levers to mimic a bionic arm!” he adds.

However, due to insufficient funds to start a venture the trio parted ways, and Matthew and Sunny joined robotics company Addverb, building mobile robots.

The three however remained connected, collaborating on smaller projects such as a UV disinfection robot, which marked the beginning of Anscer Robotics.

Incubated at IKP EDEN, a hardware incubation center in Koramangala, they built the robot. However, the pandemic ended and it did not yield success. Continuing the incubation, in 2021 they learnt that factories and warehouses faced labour challenges, prompting them to explore Hybrid Autonomous Mobile Robots (AMRs). The company launched a beta version of its product at the India Warehousing Show in December the same year.

The global chip shortage in 2022 prompted Raj Mohan, the company’s co-founder and CTO, to pitch the idea of modular technology, where the company could manufacture robots without having to rely on any external issues.

“We started building robots where every component inside it is off-the-shelf but we want the hardware IP in terms of the chassis which holds all these components. And when we did this we were able to build global standard robots made in India for India and it was very economical,” says Venkatesh.

The off-the-shelf nature of the components also allows the company to sell robots from India to US or Japan and not have a support team, he adds.

Product, operations, challenges

Anscer’s AMRs are used in internal logistics, moving equipment around the factory floor or transporting boxes and pallets within warehouses. With sector-agnostic use cases, it can be used by manufacturers across automotive, electronics, FMCG, healthcare, hospitality, pharmaceuticals, and warehousing sectors.

The robots are categorized into different series—AR, PLR, and TR—each designed for specific industrial applications.

The AR series is like a flat bed with no attachments, which the company calls the Anscer mobile platform. It allows the users to customise the top portion based on the required use case, explains Venkatesh. The AR series can lift up to 2,000 kgs.

The customisable use cases include lifting, conveyors, and collaborative robots (robot arm attached on top to automate manufacturing process). This also allows customers to reuse robots without having to buy multiple products.

The TR series includes a tugging attachment with the AR model.

Lastly, the PLR series includes pallet moving robots, which transport pallets from one location to another within a warehouse or manufacturing facility.

“The robots are designed to work in an Indian flooring environment,” explains the co-founder. With floors made of tiles, cement, epoxy etc, the company engineered its robots to work on all types of floors, including tiles, cement, and epoxy, among others, which other standardised robots couldn’t, he adds.

Inspired by NASA’s Curiosity rover and its rocker bogie system for the uneven terrain on Mars, Anscer built its robots with rocker bogie nets in its wheel systems to align flat on uneven warehouse surfaces.

Venkatesh sees Denmark-headquartered MiR, and Austria-headquartered AGILOX as its direct competitors.

Fueling the next phase

Anscer clocked a revenue of Rs 2.3 crore in FY24. While it did not share details of its FY25 results, it projects a revenue of Rs 30 crore in FY26.

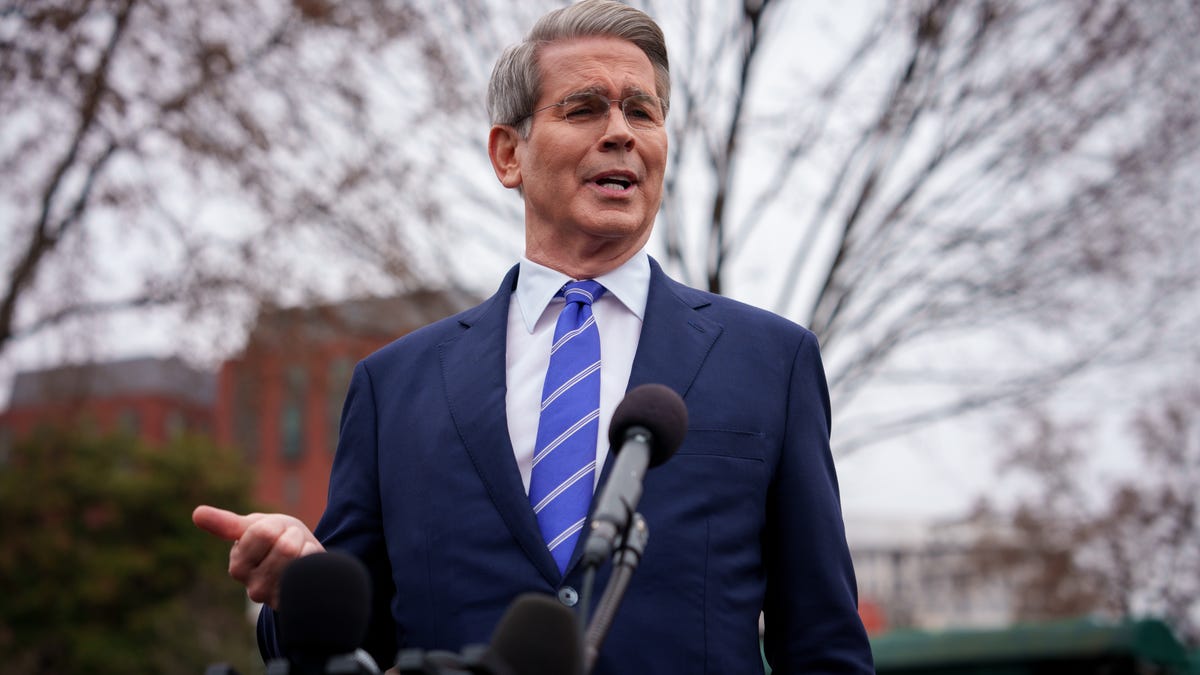

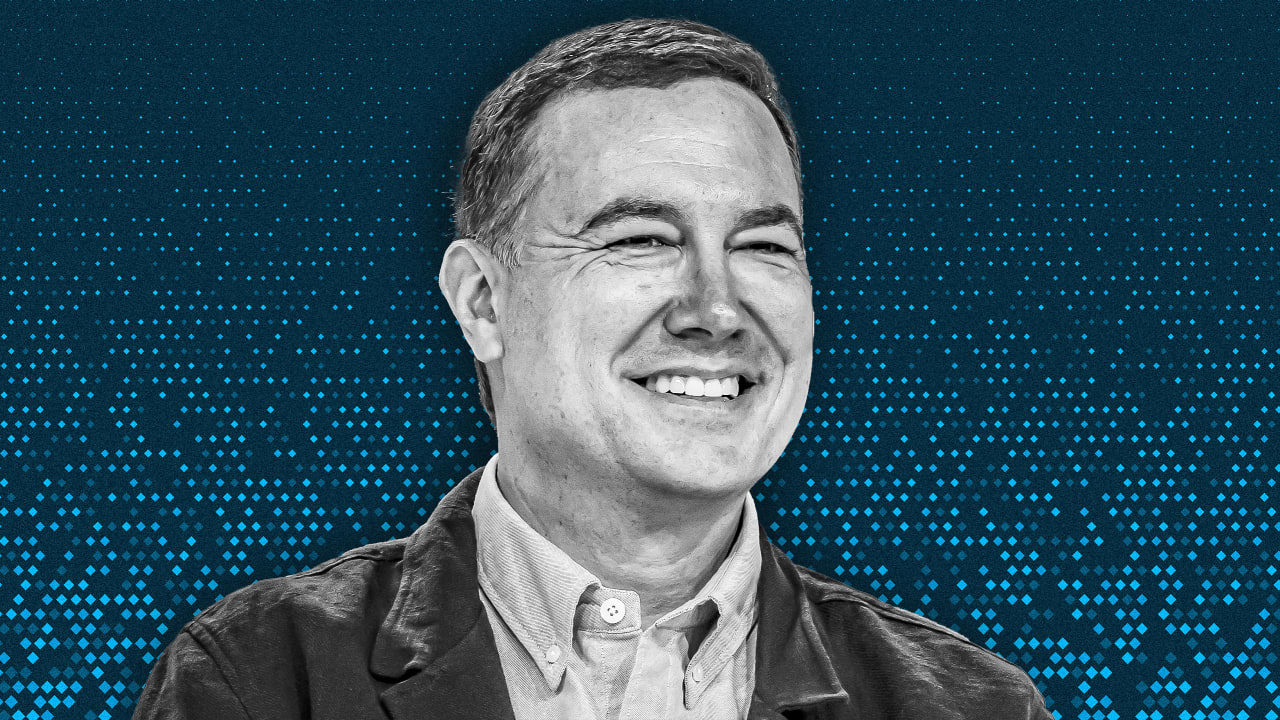

For the company’s global expansion to the US, the team roped in Mark Messina—a veteran with over 25 years of experience with various companies including , Kiva, Geek+, Philips, and Addverb—as their MD and CEO for Americas. According to Venkatesh, the company’s initial focus will be the North American and the South Asian markets.

Discussing the market in the US, he says, “At Kiva, we basically invented ATVs and AMRs as we know them today, and had Kiva not survived, it's very likely that a whole industry, including the big companies, the Chinese company, the other Indian company (Addverb), and Anscer, wouldn't have had a market for them to produce products for. But because Amazon acquired Kiva, and everybody wanted to grow like Amazon, that spawned a whole market, and it spawned a whole industry around ATV and AMR.”

Anscer’s US operations are currently headquartered at Austin, Texas, as it has a warehousing space there to keep inventory. It plans to expand its presence to Atlanta, Georgia, which is a center of warehousing and third party logistics in the U.S.

A year down the road, the company sees its US operations having several established integrators and channel partners, and direct sales to clients as well. “We very quickly want to have reference sites and we want to deploy our technology so that clients are familiar with our capabilities,” Messina adds.

A different version of a ‘similarly capable robot’ tailored to a non-harsh environment is also in the works, which would enable the company to deliver a very functional robot without all of the added costs to make it bulletproof, he concludes.