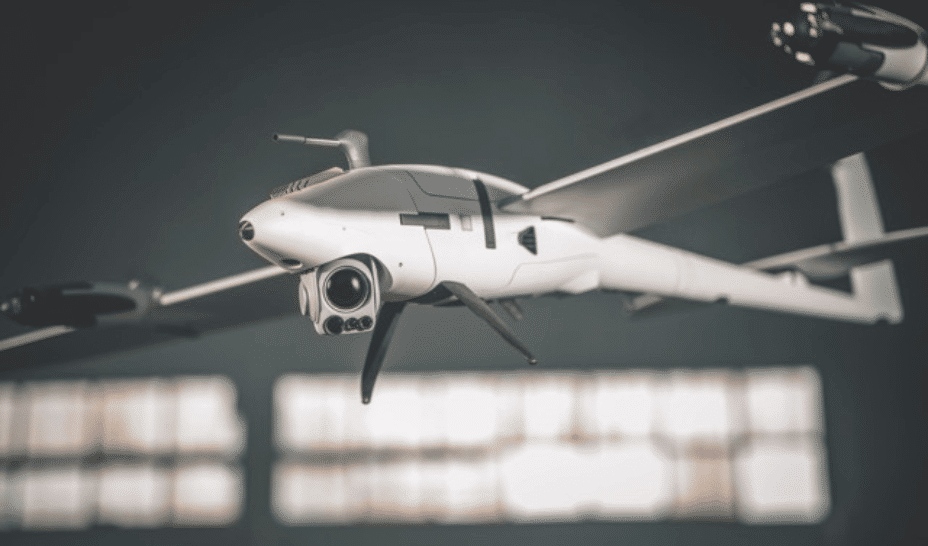

Beyond the humanoid hype: Why specialized robots will dominate the next decade

Humanoid robots inspire awe, but purpose-built robots solving hard problems will rule in the near term.

Humanoid robots are catnip for the imagination. They dazzle at tech shows, mimicking our moves with eerie precision. I’m deeply impressed by the innovations powering robots that walk, talk, and gesture like us. They represent significant technological breakthroughs that herald exciting applications ahead.

But here's the truth: They're the wrong tool for most industrial applications today, especially in some of the biggest markets, and in particular the $11 trillion supply chain.

Several humanoid robot companies have recently rolled out offerings across everything from manufacturing to elder care. Venture capital firms are investing heavily in humanoid robots, yet actual adoption in the field is slow to nonexistent.

I’m the founder and CEO of a multibillion-dollar company that was built by rejecting this one-sized-robot-fits-all-approach, choosing instead to build, orchestrate, and scale robots that are the best at what they do. That’s because I believe the next decade of robotics will be defined by specialized, purpose-built machines rather than ones that look like us. Machine systems provide better economics and operational efficiency than generalized humanoids, despite the latter’s impressive technological advances.

You can’t fight economic natural selection

Consider a simple thought experiment: Would you rather have a humanoid robot or a dishwasher wash your dishes? This is the crux of the issue: complexity versus price. The dishwasher is faster, more efficient, and vastly more cost-effective because it's designed specifically for one task.

In a real-life machine, each additional joint, sensor, and actuator has a price. A typical humanoid robot today is quite costly, with prices ranging between $50,000 and $250,000 each. Even with massive effect of scale, it will be a while before they reach the same cost efficiency as a $1,000 dishwasher. Repeat this for all sorts of problems to be solved: Will you harvest your field with an army of humanoids? Will you drive your driverless car with a humanoid in the front seat?

When Morgan Stanley estimated that Amazon’s warehouse robotics alone are projected to yield $10 billion in annual savings by 2030, they weren’t talking about humanoids. They were referring to specialized machines that excel at discrete tasks: moving inventory, sorting packages, and optimizing space.

Today’s most successful automation solutions don't try to replicate humans; they reimagine processes from first principles.

Contrast this with a humanoid robot such as Tesla’s Optimus, which might be tasked with fetching items in a warehouse. Consider what happens if Tesla reaches the holy grail of humanoid robotics: being as fast, as autonomous, as agile, and less expensive than a human operator. Then what would one do to further improve performance? Use the specialized robots to speed up the humanoid robots?

The lesson is clear: Automation excels not by imitating humans but by reengineering processes to maximize performance at the lowest cost.

When might humanoid robots make sense?

In unstructured environments where tasks vary wildly and space is designed for human bodies, jack-of-all-trades humanoids have merit if costs drop dramatically and capabilities improve exponentially—all of which are quite possible and even likely in the years ahead. Advances in specialized robots often find their way into humanoids as motors and sensors are deployed in ever larger numbers.

For instance, advancements in vision-based picking, as seen in systems like Boston Dynamics’ Stretch, enable robots to handle complex warehouse tasks with precision, adapting to varied objects in real time. These capabilities are now informing humanoid designs, enhancing their ability to navigate and manipulate environments.

For humanoids, applications inside the home may make sense, as well as any place where legs are more valuable than speedy wheels—like tight environments where terrain is unpredictable. Several humanoid robot companies have announced in-home trials before the end of 2025, hinting at this potential.

Similarly, medical wearables are seeing progress. Robotic exosuits from companies like Ekso Bionics integrate humanoid-inspired actuation and sensor technology to aid mobility for patients, pushing the boundaries of human-robot interaction. These use cases drive economies of scale for components, propelling the broader robotics ecosystem forward.

But supply chain operations are the opposite of this scenario, and the constraints aren’t forgiving. They're highly structured environments where tasks are predictable and repetitive. The economics of purpose-built systems will always win in these scenarios, which is why Amazon, after acquiring Kiva Systems (now Amazon Robotics) for $775 million in 2012, doubled down on specialized robotics rather than pursuing the humanoid path.

Return on robotics: the new ROI

I am optimistic that humanoids’ dramatic price drop and performance upgrade will happen over the next decade and will add incredible dimensions to human life—and finally help me to stop folding laundry.

Until then, businesses serving customers and investors must drill into their return-on-robotics investment. In warehouse automation, it comes down to critical operational performance: speed, volume, and precision of inventory retrieval, all weighed against the cost of the robot and ongoing operational costs. That demands robots honed for the job—and meeting today’s high bar for performance. Today, most purpose-built robotics companies promise payback in five years or so—an impressive start for a nascent industry that will only improve.

Moreover, the market continues to grow rapidly. As McKinsey notes, some experts foresee robot shipments growing by 50% per year, with warehouse automation growing north of 10%. Businesses simply can’t wait for robots; they need them now and in the near future to overcome the global labor crunch and stay ahead of rigorous customer expectations.

Humanoids inspire awe. Yet I believe the next 10 years will be ruled by purpose-built robots solving hard problems with lean solutions that maximize productivity from every inch of operations and pay for themselves many times over.

For now, don’t bet on robots that mimic your walk—invest in ones that run your business better.

The opinions expressed in Fortune.com commentary pieces are solely the views of their authors and do not necessarily reflect the opinions and beliefs of Fortune.

Read more:

- Meet the growing army of Amazon robots working alongside humans to reduce workplace injuries

- Gecko Robotics CEO: How I bucked Silicon Valley’s monopoly on frontier tech

- Some manufacturing jobs will return to U.S. only if AI robots do them

- Elon Musk claims Tesla is the top robot company but worries that Nos. 2 through 10 will be Chinese

This story was originally featured on Fortune.com