‘Our DNA is heavily product-centric’: Indkal Technologies CEO on developing Acer devices in-house

‘Our DNA is heavily product-centric’: Indkal Technologies CEO on developing Acer devices in-house Acer has launched two new homegrown phones, the ZX and ZX Pro. They are made by Bengaluru-based electronics company Indkal Technologies. The Acer ZX is positioned as a practical device for everyd

Acer has launched two new homegrown phones, the ZX and ZX Pro. They are made by Bengaluru-based electronics company Indkal Technologies.

The Bengaluru firm, which previously engineered Acer's television and appliance lines for the Indian market, spent two years developing the 5G phones with competitive specifications.

The Acer ZX is positioned for everyday use and costs Rs 9,990. It features a large 6.78-inch LCD display with full HD+ resolution and a refresh rate of 120Hz, which allows for smoother animations and scrolling. Meanwhile, the Acer ZX Pro, priced at Rs 17,990, is a more advanced alternative for users seeking improved design, display quality, and photography performance.

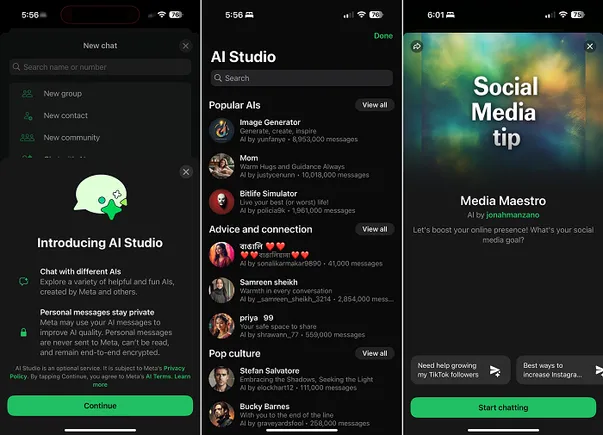

Indkal Technologies is a unique player in India’s consumer electronics space. The company began its journey licensing the Acer trademark for televisions and later, surprisingly, washing machines—a bit of an odd foray for a brand better known globally for computing products.

But these weren’t rebadged imports. The washing machines were developed entirely in-house, tailored for Indian households and built from the ground up by Indkal’s R&D team.

“R&D is our largest manpower expense. We have a robust in-house engineering team, along with dedicated divisions for PCB design and validation. We also work with design solution partners when necessary. Our company DNA is heavily product-centric,” Anand Dubey, CEO, Indkal Technologies, tells YourStory. Appliances made by Indkal Technologies

Now, Indkal is applying this same playbook to smartphones. The Acer-branded phones are conceptualised, designed, and engineered by Indkal's team in India and have been in the works for two years. ZX is equipped with a triple camera system on the back, including a 64 MP sensor for high-resolution images, and is powered by the Mediatek 6300 chipset.

Performance-wise, the ZX Pro is powered by the Mediatek 7400 chipset and offers more memory and storage options compared to the ZX. The Pro also offers an in-display ultrasonic fingerprint sensor and higher protection against dust and water.

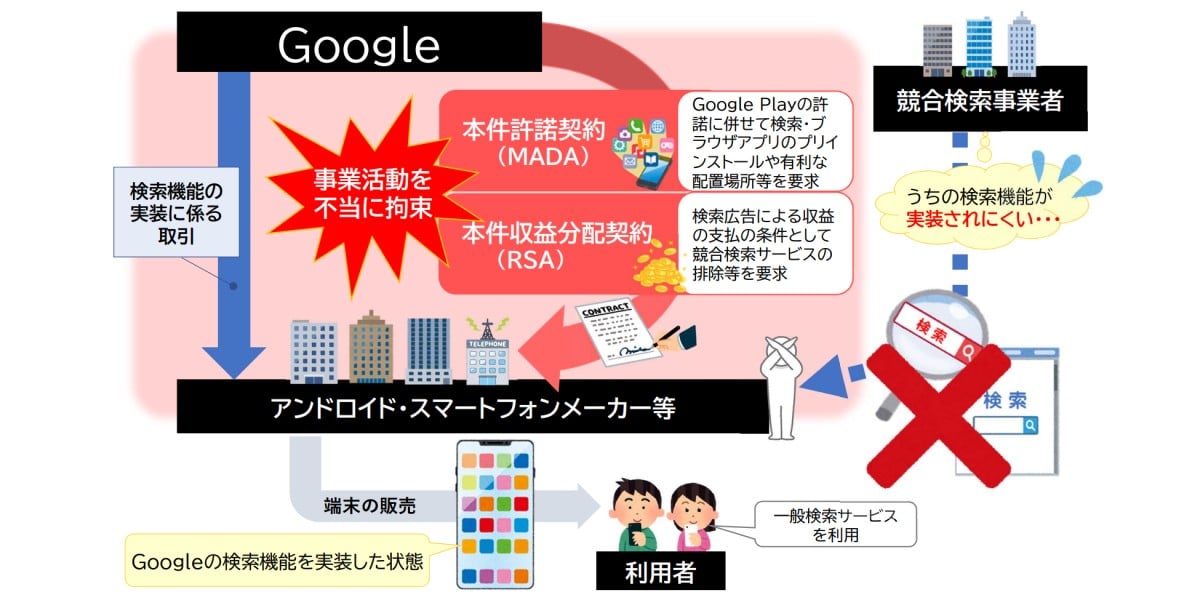

While Acer provides the brand license and ensures alignment on quality and design language, Indkal claims full ownership of the product development lifecycle—from chipset integration and component selection to software optimisation.

In a conversation with YourStory, Dubey delves into the journey to creating Indkal, its focus on R&D and in-house product development, and its partnership with Acer.

YourStory [YS]: Indkal started with Acer-branded TVs and even washing machines, which seems unusual for the Acer brand. What was the thinking behind that for Indkal Technologies?

Anand Dubey [AD]: We looked at the ecosystem and felt very strongly that Indian participation in this industry was limited. What we consume as Indian customers in consumer electronics and durables was global in nature, not created specifically for India. We were in a great position with our technical capability and our ability to innovate in products to create those minor and major changes, modifications, and improvements.

YS: Can you give examples of India-specific innovations in your existing products?

AD: In TVs, we became the first company in India to launch a QLED display in a 32-inch size, disrupting the notion that 32-inch was only a price play. We also launched the first Android 14-based Google TVs in India, using a processor architecture not typically seen in TVs (ARM A55 and A75 combination) and incorporating a 2.2 audio system for better sound depth, as Indian customers often don't buy separate soundbars. In air conditioning, we launched a 7000 British Thermal Units (BTU) capacity AC because the heat in India is much stronger, so we needed something more powerful yet appropriately priced.

YS: You emphasise in-house R&D. How significant is this to Indkal's strategy?

AD: R&D is our largest manpower expense. We have a very large R&D team and quality management team, which allows us to work on multiple products simultaneously. We have dedicated teams working on component solutions like PCB design, manufacturing, and validation. The DNA of the company is all about building new products, improving or optimising technology, and creating better, interactive technology for customers.

YS: How did the partnership with Acer come about, and what kind of guardrails does Acer set?

AD: The conversation started a long time back; we knew each other and our respective strengths from my consulting background. It was a very straightforward process to enter into the trademark license arrangement. There are always inputs from Acer on design language and product specs. There's also very strong management regarding how quality control and product development are handled. Most of the guardrails are set around the product's quality—hardware, software, validation of components, and the product as a whole. These parameters are agreed upon between us and Acer.

YS: What is Indkal's distribution strategy?

AD: We're an omnichannel company. We work heavily through ecommerce. We also have a very large offline distribution setup with more than 140 distributors across the country covering TVs, washing machines, ACs, refrigerators, and now smartphones. Additionally, we work within modern trade, being present in national large-format retail chains like Reliance Digital, as well as other regional retail stores. Currently, we have almost an equal split between offline and online sales, with offline being slightly larger.

YS: You work with manufacturing partners like Dixon instead of manufacturing yourself. What is the thought process behind it?

AD: We strongly subscribe to using manufacturers while developing products on our own because the roles are well-defined. Manufacturing is an operationally heavy process requiring efficiency and process adherence, which partners like Dixon do very well. R&D, building IPs, and innovation must be the fundamental base for what we are trying to create as an economy. To become a manufacturing hub, it's important that we not only focus on a small part of the value chain but also start building the entire value chain ourselves. This requires innovation, creating new products, and disrupting existing technology. Can we create the next evolution in TVs or washing machines? That's the direction we need to move in, building the infrastructure to support innovation and experimentation.

YS: Are there plans to take these Indkal-developed Acer products beyond India?

AD: For now, India remains the focal point for us. This market is immense in terms of size, and the scope remains largely untapped in many areas. For instance, air conditioning penetration in India is still under 10%, whereas developed economies might see over 50%. We expect India will eventually reach higher penetration levels. This means the Indian market presents an overwhelmingly large opportunity, unlike anything most companies have seen. Therefore, our focus needs to remain here in India. We will re-evaluate international expansion once we have made more headway with our growth in India and have captured a larger part of what we aim to achieve domestically.

Edited by Jyoti Narayan

![How to Find Low-Competition Keywords with Semrush [Super Easy]](https://static.semrush.com/blog/uploads/media/73/62/7362f16fb9e460b6d58ccc09b4a048b6/how-to-find-low-competition-keywords-sm.png)