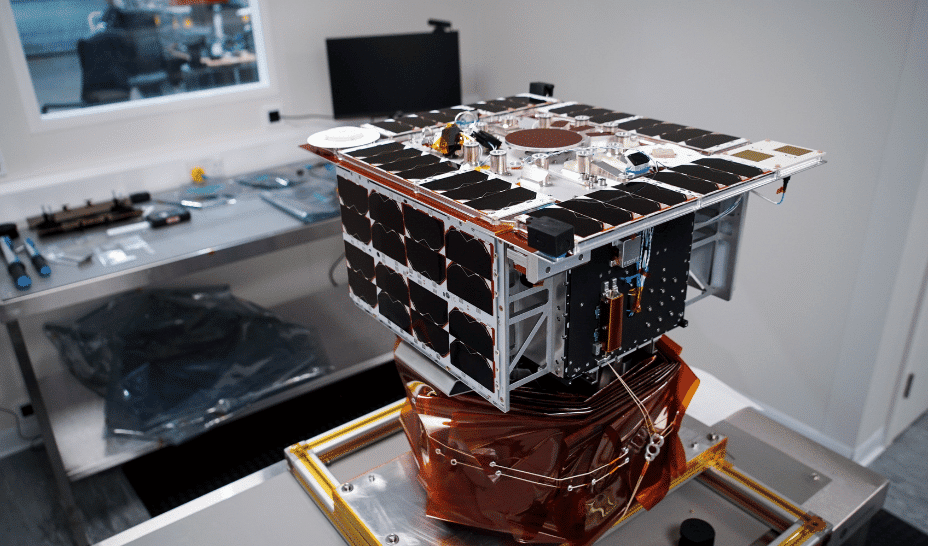

InventWood Is About To Mass-Produce Wood That's Stronger Than Steel

Longtime Slashdot reader ndsurvivor shares a report from TechCrunch: In 2018, Liangbing Hu, a materials scientist at the University of Maryland, devised a way to turn ordinary wood into a material stronger than steel. It seemed like yet another headline-grabbing discovery that wouldn't make it out of the lab. "All these people came to him," said Alex Lau, CEO of InventWood, "He's like, OK, this is amazing, but I'm a university professor. I don't know quite what to do about it." Rather than give up, Hu spent the next few years refining the technology, reducing the time it took to make the material from more than a week to a few hours. Soon, it was ready to commercialize, and he licensed the technology to InventWood. Now, the startup's first batches of Superwood will be produced starting this summer. "Right now, coming out of this first-of-a-kind commercial plant -- so it's a smaller plant -- we're focused on skin applications," Lau said. "Eventually we want to get to the bones of the building. Ninety percent of the carbon impact from buildings is concrete and steel in the construction of the building." To build the factory, InventWood has raised $15 million in the first close of a Series A round. The round was led by the Grantham Foundation with participation from Baruch Future Ventures, Builders Vision, and Muus Climate Partners, the company exclusively told TechCrunch. How do they do it? According to TechCrunch, InventWood's Superwood is made by treating regular timber with "food industry" chemicals to remove lignin and modify its structure, then compressing it to increase hydrogen bonding between cellulose fibers. This densification makes the wood up to 10 times stronger than natural wood, with a higher strength-to-weight ratio than steel. "You end up with something that looks like these richer, tropical hardwoods," Lau added. Read more of this story at Slashdot.

Read more of this story at Slashdot.