Inside Amazon’s sustainability lab: Grueling tests forge the future of planet-friendly plastics

In its pursuit of planet-friendly plastics, Amazon is putting candidate materials through a series of devices that recall medieval torture methods. Plastic films are slowly stretched to the point of breaking. They’re sliced with a blade on tiny pendulum, poked until they puncture. At the Amazon sustainability lab — an uncluttered, windowless space in the industrial zone south of Seattle’s sports stadiums — researchers are testing new plant-based “biopolyesters” that could one day be used in carrot bags, potato chip packages and clamshell containers for fresh berries. While a significant challenge, Amazon’s ambitions in this sphere extend well beyond the… Read More

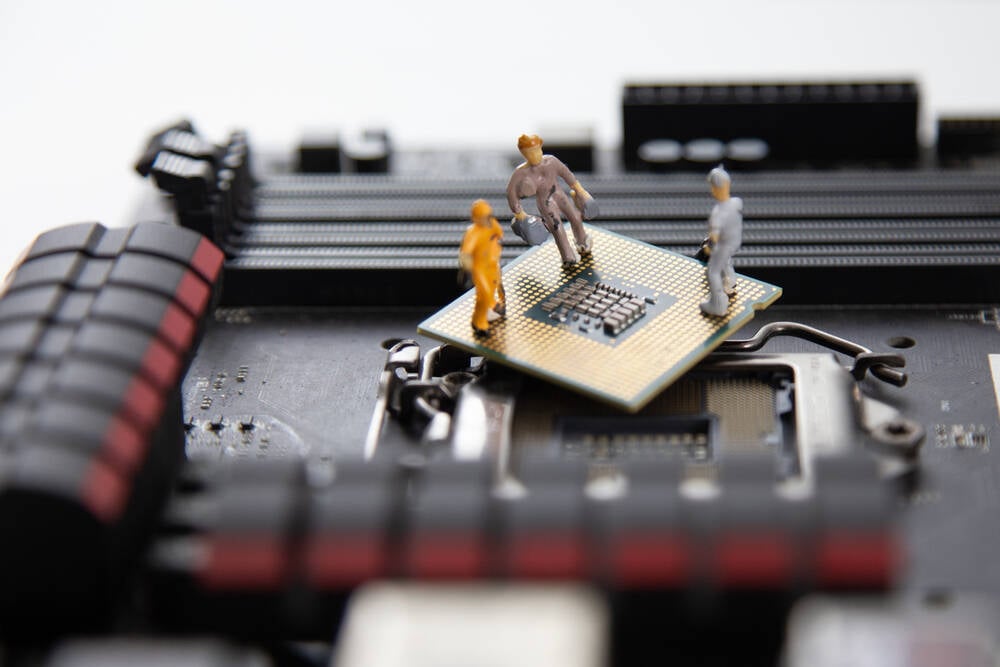

In its pursuit of planet-friendly plastics, Amazon is putting candidate materials through a series of devices that recall medieval torture methods. Plastic films are slowly stretched to the point of breaking. They’re sliced with a blade on tiny pendulum, poked until they puncture.

At the Amazon sustainability lab — an uncluttered, windowless space in the industrial zone south of Seattle’s sports stadiums — researchers are testing new plant-based “biopolyesters” that could one day be used in carrot bags, potato chip packages and clamshell containers for fresh berries.

While a significant challenge, Amazon’s ambitions in this sphere extend well beyond the development of green plastics. The tech and retail giant is reimagining the entire food packaging system from materials, to waste collection, to recycling and reuse of the environmental plastics.

The goal is an easy-to-use, cost-competitive, scalable solution that will speed the transition away from fossil fuel-based plastics that harm the climate and add to the glut of plastic pollution around the globe.

At its Seattle lab, Amazon is searching for a super plastic that needs to be recyclable as well as biodegradable if it gets tossed in the trash or littered in the environment. But it also needs to keep fruits and vegetables fresh, salty snacks crispy, and hold up as packaging for frozen foods.

“There’s no technical reason why that’s not possible,” said Alan Jacobsen, Amazon’s director of materials and energy science. “We’re trying to put the pieces in place to make that feasible.”

Potential end-users of the packaging include Amazon Fresh, the company’s grocery delivery service and supermarkets; its grocery subsidiary Whole Foods; as well as any other company seeking eco-friendly solutions.

“This is not something we’re developing just for Amazon,” Jacobsen said. “The work we’re doing here, we want to make available to anyone that can use it. For any type of new material to work on the market, and for you to have a viable recycling stream, it has to be used by many different brands.”

Amazon’s environmental ambitions

Amazon has promised to reduce its climate emissions to net-zero carbon by 2040, and has recruited more than 550 organizations to join it by signing The Climate Pledge.

Amazon’s emissions, however, are up 34% since it made its climate commitment in 2019. Its carbon footprint did shrink 3% in 2023 over the previous year. Adopting greener plastics could help in moving toward its carbon goal.

The company opened the Seattle lab about six years ago. Amazon operates four other sustainability research facilities in the U.S. and Europe targeting improvements in packaging for shipping, its electronic devices, technologies used in buildings, and operations innovation.

Critics have attacked Amazon for its plastic waste in shipping and the company has taken steps to reduce its impact. In October it announced the end of the inflated plastic pillows used to cushion goods shipped to customers, replacing them with recycled paper as a filler.

Oceana, an environmental watchdog, has applauded these and other efforts, but calls on Amazon to do more. “The company should continue to publicly report on its plastic packaging footprint for all products sold through Amazon’s website and report and take responsibility for the full climate impacts of all products sold and packaging use through Amazon’s website,” Oceana stated online.

Changes take longer in the grocery space. In one of its first pilot projects, the company in January shared that it’s testing bio-plastic bags for Amazon Fresh deliveries in Spain.

Amazon shareholders rejected a proposal last year requesting the company report on the total amount of plastic that it uses and how it could reduce its plastics footprint.

Partners in a circular system

Amazon’s materials lab partners with multiple companies worldwide that produce the biopolyesters, which can be made from products such as vegetable oil and different kinds of sugar, or non-edible feedstocks such as corns stalks and husks and other agricultural waste.

The manufacturers provide samples that Amazon researchers test for durability and performance under wide-ranging conditions. They study how porous the biopolyesters are to water and oxygen, and at what temperature they melt for packaging that needs to be sealed.

The company is also collaborating on the recycling of the new plastics. The vision is to integrate the biopolysters into the existing waste-collection infrastructure so they can be easily recycled alongside other plastics, cans and bottles.

It’s working with and has invested in Glacier, a San Francisco waste technology company, to develop AI-enabled robots that can recognize biopolysters and sort them out for recycling. Amazon has also teamed up with EsterCycle, a Denver-based startup developing a chemical process for recycling the biopolyesters and similar plastics.

It will take time before plant-based plastics are more commonplace, but Jacobsen is hopeful.

Maybe in the next couple of years, there won’t be a lot of change, he said. “But in 10 years, I’m very optimistic.”

![How To Align the SEO Process With AI Discovery [Infographic]](https://imgproxy.divecdn.com/9P2R5ZZoepHyBzf0CW-n2EgWRhr-_OdwsznROe_GvnM/g:ce/rs:fit:770:435/Z3M6Ly9kaXZlc2l0ZS1zdG9yYWdlL2RpdmVpbWFnZS9haV9zZWFyY2hfaW5mbzIucG5n.webp)