German AI startup akeno raises €4.5 million to automate production planning

Hamburg-based akeno has raised €4.5 million in a Seed funding round to scale its AI-driven production planning software, marking a step forward in the digital transformation of the manufacturing sector. The round was led by Cusp Capital, alongside TS Ventures and another.vc. “Anyone who plans their production based on outdated master data runs the risk […] The post German AI startup akeno raises €4.5 million to automate production planning appeared first on EU-Startups.

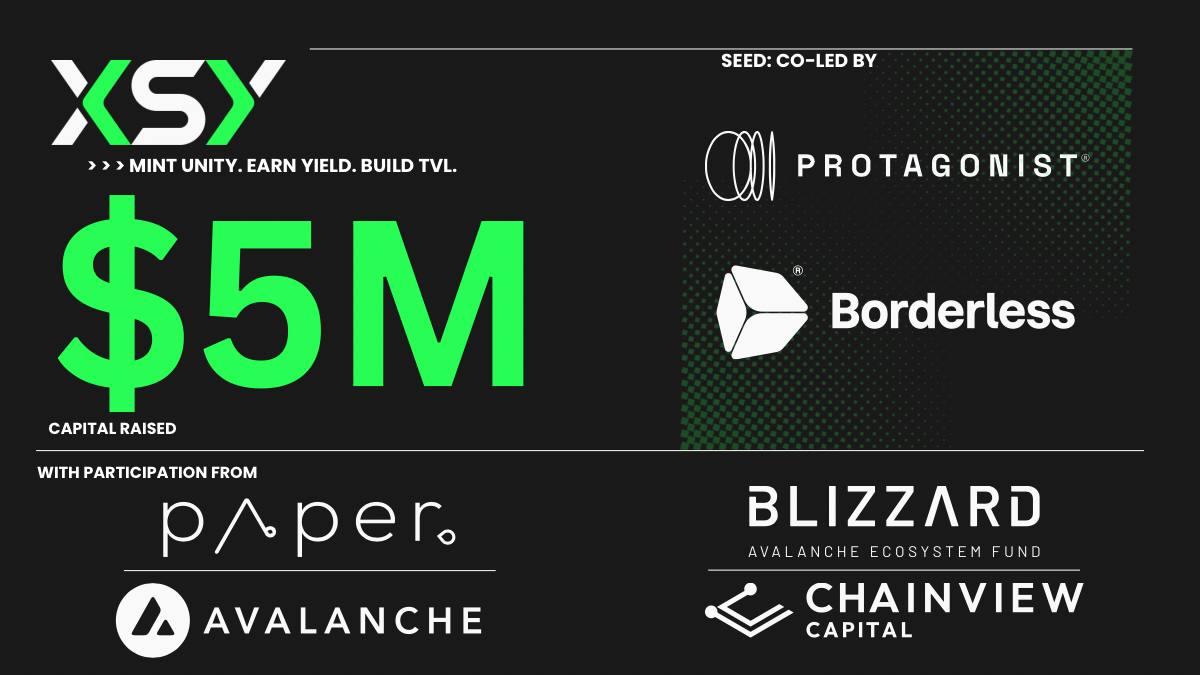

Hamburg-based akeno has raised €4.5 million in a Seed funding round to scale its AI-driven production planning software, marking a step forward in the digital transformation of the manufacturing sector.

The round was led by Cusp Capital, alongside TS Ventures and another.vc.

“Anyone who plans their production based on outdated master data runs the risk of losing their competitive edge,” says Co-founder and CEO Alexander Ebbrecht. “Our long-term vision is to fully automate production planning, enabling our software to autonomously adapt to real-world events and conditions and optimise production plans in real time.”

Founded in 2021 by Alexander Ebbrecht, Dmitrij Direktor and Steffen Ramm, akeno is tackling one of manufacturing’s long-standing headaches: outdated production plans. The company’s software analyses real-time production data to automatically adapt planning schedules, offering an alternative to Enterprise Resource Planning (ERP) tools like SAP.

This approach has already won over industrial players such as BASF Coatings, SunChemical and the Beckers Group.

akeno’s platform targets process-heavy sectors such as chemicals, pharmaceuticals, and food manufacturing — industries where precision and flexibility are essential. The software integrates with existing infrastructure and uses operational data such as machine status and material availability to predict potential disruptions and optimise production plans.

Its self-learning algorithms reportedly build a deeper understanding of workflows over time, enabling increasingly accurate and efficient production scheduling.

In pilot projects, akeno has demonstrated the ability to anticipate machine downtime, identify unexpected production windows, and dynamically reassign work orders — all without human intervention.

The rollout with BASF Coatings is a key milestone, with the multinational citing akeno’s potential to optimise and streamline its global production workflows.

“BASF Coatings is excited to be working with akeno on an innovative project to enhance its production planning and scheduling. Their product promises to bring a new level of optimisation and comprehensiveness to our processes,” explains a representative of BASF Coatings.

The funding will be used to triple the team’s headcount, accelerate product development, and support international expansion. akeno has already entered the Chinese market and plans to move into North America and further Asian territories next.

“akeno uses the increasingly available operational technology data for AI-based, real-time optimised production planning. The solution achieves impressive results such as higher plant utilisation and reduced working capital. The focus is currently on the chemical industry, but other batch industries such as pharmaceuticals and food are also benefiting. However, many companies are still working with outdated tools and reactive processes,” says Dr Maximilian Rowoldt, Investor and General Partner at Cusp Capital. “akeno has the potential to become a central building block in the digital infrastructure of industrial companies and to strengthen Europe’s competitiveness.”

By shifting production planning from fixed schedules to dynamic, learning-based systems, akeno is positioning itself at the forefront of industrial AI — a sector where timing is everything.

The post German AI startup akeno raises €4.5 million to automate production planning appeared first on EU-Startups.

![What Are Website Demographics? [Explained]](https://static.semrush.com/blog/uploads/media/e3/e4/e3e48631e5cd307cd7a4bfee26498e62/0db9c37107a24c016f06d29ca0a5719a/website-demographics-sm.png)

![An Ad Quality Control Checklist [Infographic]](https://imgproxy.divecdn.com/6nIRujQEJFAZ7N9aiG3W8ZdvYsZHRQGEYXyTvI-9_h8/g:ce/rs:fit:770:435/Z3M6Ly9kaXZlc2l0ZS1zdG9yYWdlL2RpdmVpbWFnZS9hZF9xdWFsaXR5X2NoZWNrbGlzdDIucG5n.webp)